|

| Photo 1 – The ridge tillage system used at Hackmatack Farm essentially means we grow crops in single-row raised beds. |

|

| Photo 2 – Onions in July. |

|

| Photo 3 – Forming ridges in the spring. |

|

| Photo 4 – Ridged soil in the spring |

|

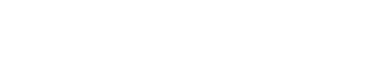

| Figure 1 – Depending on the crop, either one, two or three rows are planted down each ridge. |

|

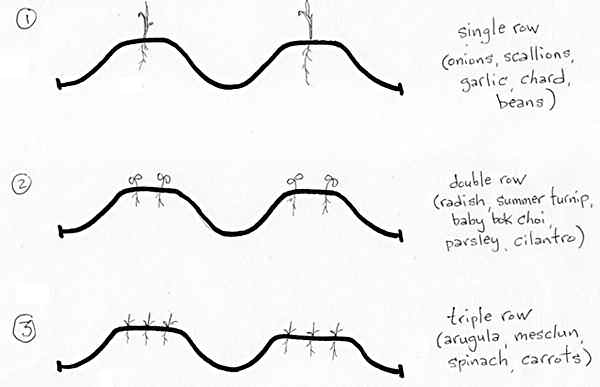

| Figure 2 – Ridge tillage, at the bottom of the figure, creates a greater area of topsoil and biotic root zone than raised or level beds. |

|

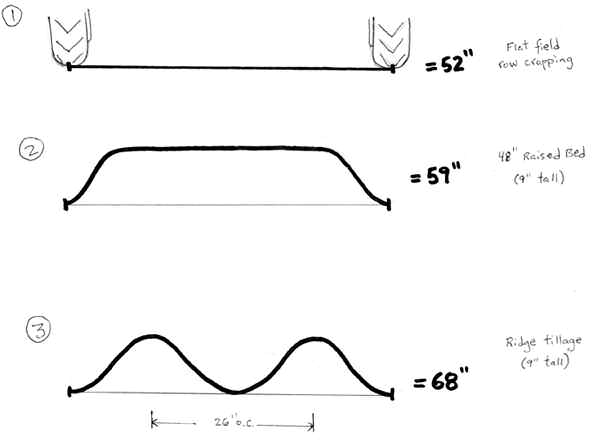

| Figure 3 – The many small mountains and valleys in a ridge tillage system create warmer soil earlier and minimize wind and water erosion. |

By Nicolas Lindholm

All photos and illustrations © Nicolas Lindholm

Ridge tillage is a system where you grow vegetable crops in raised ridges formed before planting. It’s essential to incorporate winterkilled cover crops and other organic matter into the top surface layer of soil as we form the ridges. Practically speaking, our crops grow on a single-row raised bed. (Photos 1 and 2)

Ridge tillage, in essence a hybrid between raised bed production and single row cropping, offers many of the benefits and advantages of both. With the added component of full-year cover cropping (a field is taken out of vegetable production every second or third year), this system creates soil conditions that favor proper air movement, water movement and residue decay, minimize soil damage or loss, break weed cycles and deplete the weed seed bank, and demand relatively low-intensive management by the farmer.

We designed our system focused on the soil and tillage, as a whole farm system – all other systems for our vegetable crop production (weed control, pest control, fertility, irrigation, labor, etc.) fall under and within the overall scheme of our ridge tillage system. It is a reduced or minimal tillage system in which we use a 32 hp tractor and three basic tillage tools. Once every third year (at the beginning of the cover crop year), we plow with a moldboard plow. We use a disc harrow to prep and cover and eventually turn in cover crop plantings (three per year); we also use the disc harrow to clean up vegetable rows after harvest. The main tool, however, is our ridge-former tool – simply a 3-point-hitch double tool bar with assorted discs and sweeps mounted on it. (Photo 3) We use this once every spring to form the vegetable ridges (Photo 4) and two or three times in early summer to cultivate established crops. We also set this tool bar up with three large shanks for occasional deep ripping if needed or desired.

Going into our eighth year of this system (and our 18th year of MOFGA certified organic vegetable production on most of our fields), we are maintaining levels of organic matter in the 8.0 to 8.9 percent range on our very stony glacial till loam. In 2013, we grossed the equivalent of $40,000 per acre for our vegetable operation, averaging $2.51 per row foot. We are adding only small amounts of compost, manure or other off-farm inputs (straw, seaweed, rock powders, fish meal) and practice a high-residue cover cropping plan.

The typical cover crop or fallow year starts with a planting of oats and peas in spring, followed by buckwheat in midsummer, and by oats, peas and barley in late summer to be winterkilled. We often incorporate compost or manure in this year. Two years in vegetables follow the cover crop year, with different crop families being easily mapped within the ridge system so that no section of field grows the same vegetable family for a minimum of five years, often longer.

We form ridges early in spring, as soon as the ground can be worked, incorporating the winter-killed cover crop into the ridges. In our system, we form two ridges between the tractor tires (set 52 inches apart), so the ridges end up being 26 inches center-to-center. When first formed, our ridges are typically 12 to 14 inches high; after planting and cultivating throughout a season, they end up around 9 inches high.

To plant, we scalp the crest of the ridge with a rake, incorporate soil amendments with a narrow cultivating scratcher, and then smooth the seedbed with the rake. We use an Earthway seeder for most direct-seeded crops, or transplant into the scalped and prepared ridge.

Depending on the crop, we plant either one, two or three rows down each ridge. (Figure 1) Crops for single-row planting include onions, scallions, shallots, leeks, garlic, chard, spinach, beans and head lettuce. Crops planted in double rows include radish, summer turnip, baby bok choi, parsley and cilantro. We use triple-row plantings for arugula, mesclun and lettuce mixes, and carrots.

Certain crops require a wider “bed,” and for these we instigate a “doubled-ridge” formation. We set the outer discs of the tool bar slightly closer together and remove the inner discs and sweep, creating a bed about 40 inches wide with a shallow valley down its center. We apply soil amendments into the valley, cover the bed with 48-inch-wide black plastic mulch, and then transplant tomatoes, zucchini, cucumbers and melons down the center valley. We plant potatoes the same way, but without black plastic, and hill them with discs on the tool bar.

We use the same 3-point-hitch toolbar in differing configurations to cultivate most crops until they are too tall for our tractor. Typically our quick-growing greens, such as mesclun, arugula, summer turnip, etc., don’t require cultivation; many crops (chard, beans, head lettuce, onion family) require one or two tractor cultivations followed by either straw mulch in the narrow pathways or quick hand-hoeing for weed control for the rest of the growing season. The slopes of the ridges are well suited for ease of cultivation, allowing discs to throw more soil up onto the side of the ridge or, with very shallow hoeing (we use a collinear hoe), readily allowing soil to shift and weeds to fall into the pathway between ridges.

The expanded spacing provided by the bio-extensive system in concert with favorable air and water flow through the soil provided by the high-residue cover cropping minimizes irrigation needs. When we do need or want to water, we move hoses and sprinklers into the field. Good airflow above ground, in and around the crop, also naturally provided in this system, helps minimize or mitigate disease pressure.

Ridge tillage significantly impacts the soil ecosystem by arranging topsoil in a way that enlarges and optimizes the volume most used by plant roots and the diverse ecology of microorganisms that promote plant growth and health. Figure 2 shows three cross-sectional views of different vegetable bed configurations. View 1 at the top shows an old-fashioned, flat field row cropping, with 52 inches of soil to use between the tractor tires or pathways. View 2 shows a typical 48-inch-wide (at the base) raised bed, which, at 9 inches tall, measures 59 inches along the soil surface, from side to side between the same tractor tires. View 3, our ridge tillage system, shows two raised ridges, each 9 inches tall, which together measure 68 inches along the soil surface from side to side – 30 percent more than the flat field and 15 percent more than the typical raised bed.

This expanded surface area of soil is highly beneficial. The top 3 inches of a vegetable field or garden soil, especially in a high-residue system, is where most of the macro and microorganisms live, so ridge tillage expands and increases this “bioactive zone.” Transitional or edge ecologies, such as at the forest’s edge or the ocean shore, are highly biotic zones where many forms of life thrive and biological activity is greater than in other, non-transitional ecosystems. In our vegetable fields, simply creating ridge formations expands this biotic zone along the surface of the topsoil (and the biotic root zone just under the soil surface).

Moreover, the physical shape of the field that our ridge tillage system creates actually enhances the positive impacts and mitigates the negative impacts of natural forces such as sun, wind and rain. Figure 3 illustrates the benefits of all these tiny mountains and valleys created in the vegetable field.

Such a system is highly adaptable to varying equipment and labor needs, soil types and farming preferences. We designed and chose this system for several personal reasons:

• We wanted to minimize labor requirements for our vegetable operation, with little or no dependence on off-farm hired or apprentice help. We cultivate about 1 1/2 acres for vegetables, with the equivalent of one full-time person May through August, one part-time person March through October, and one hired part-time employee for July and August. Our certified organic wild blueberry operation requires up to a dozen employees, so our time, especially in August, is precious and we needed a vegetable production system that did not require large amounts of time and management.

• We wanted to minimize costs of capital equipment. It was important to strike a balance between mechanization and reliance on lots of different, costly equipment. We wanted low-tech, multi-purpose equipment with minimal investment. One tractor with one adaptable tool is at the heart of our system.

• We wanted to minimize tillage and improve soil structure. Before 2006, we had been using a BCS rototiller on a 42-inch-wide raised bed system and saw diminishing tilth and air and water flow through the soil with increasing weed and disease problems. All that has now been reversed.

• We wanted to minimize input costs and reliance on off-farm purchases for fertility, soil-building and crop growing. Bio-intensive raised bed systems require high levels of fertility and greater irrigation; our bio-extensive system, using more space more wisely, improves soil and soil-life conditions with fewer inputs.

Our ridge tillage system uses relatively low-cost equipment, low intensity of inputs, and low labor demands. Properly incorporated cover crop residue allows plants to use more of the top 3 inches of soil (the bioactive zone) compared with flat row cropping and raised beds, and it simplifies management of soil air and water as it improves aeration and water flow/capillary action within the soil – all with fewer passes and less tillage compared with the other systems. It works with low power and low-tech cultivators (of which many options/types will work, including more expensive and refined planting and cultivating equipment) and is adaptable to almost any soil type (clay, sand, loam, etc.) or primary power source (horse or tractor).

Farming in the face of global climate change, we are impressed with the resiliency of our fields after extreme weather events, whether heavy rain, wind, drought, unseasonable high or low temperatures, etc. The soil on the ridges dries and warms earlier and more evenly in spring and recovers more readily after a heavy storm or odd weather pattern during the growing season.

Do I advocate for more farmers to use ridge tillage? You bet.

About the author: Nicolas Lindholm and Ruth Fiske raise MOFGA certified organic produce at their Hackmatack Farm in Penobscot, Maine, selling it primarily through farmers’ markets in Stonington, Deer Isle and Castine, as well as to the Blue Hill Coop and a few other select markets in the Blue Hill area. Nicolas also volunteers his time on MOFGA’s agricultural services committee.

MOFGA has a two-row ridge-till toolbar modeled after Nicolas’ equipment in the shared-use farm equipment program hosted in Unity. This toolbar is easily adaptable to a variety of situations and is intended to give growers an idea of how this system might work on their farm. For more information about the toolbar, contact Katy Green at [email protected].

This article is available as a PDF download (Fact Sheet 21 – 3 pages, 1.3Mb)